Accuity

Accuity

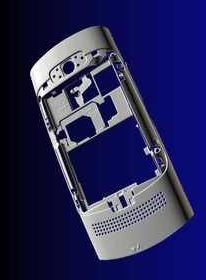

The Accuity is the most automated, large field of view, telecentric gauging system on the market, and can scan in both 2D and 3D as standard.

InspecVision introduce our latest product to the market. The Accuity system has a certified accuracy from 6 microns, and can scan parts greater than 160mm diameter. The total setup and inspection time for a new part is unrivaled, at around 4 seconds.

Automated 2D & 3D Inspection

Set up times and user input are reduced to zero by importing dimensions and tolerances from the CAD file. The total setup and inspection time for a new part is unrivalled, at around 4 seconds.

3D Scanning is included as standard, allowing inspection of each feature in both 2D and 3D. Parts can then be compared to both 2D and 3D CAD models, or inspected without a CAD model. The system has no moving parts making it shop floor friendly.

20MP cameras and HD projectors produce accurate measurements traceable to ISO10360-4. Ensuring fast inspection times at high resolutions with minimal setup.

2D Key Features

- 20MP camera as standard

- No moving parts

- Scans entire field of view with each scan

- 4 second setup and inspection tim

- Large depth of field 60mm

- Automatic report generation, zero setup

- Automatic alignment, no fixtures required

- Identification of bad parts and features

- Extensive support features for off site system analysis

- Traceable results, ISO10360-4

- Temperature compensation

- Inspect multiple parts at once

- High speed reverse engineering

- Re-positioning and merging of scan data

3D Key Features

- Captures texture and 3D shape

- Scans entire field of view in less than 10 seconds

- Check angles heights and cross-sections

- Measures edges in 3D

- Compatible with free 3D inspection software

- Comparison with 3D Solid Model

- GD&T inspections in 3D

- Projection of flatness deviation onto part

- 10 second scan time

- Augmented reality projection of failed features onto parts

- HDR scanning for reflective and high contrast components

Automated 2D & 3D Inspection

Set up times and user input are reduced to zero by importing dimensions and tolerances from the CAD file. The total setup and inspection time for a new part is unrivaled, at around 4 seconds.

3D Scanning is included as standard, allowing inspection of each feature in both 2D and 3D. Parts can then be compared to both 2D and 3D CAD models, or inspected without a CAD model. The system has no moving parts making it shop floor friendly.

20MP cameras and HD projectors produce accurate measurements traceable to ISO10360-4. Ensuring fast inspection times at high resolutions with minimal setup.

Modele

| Model | Accuracy | Max Component Size (mm) | Max Component Weight (kg) | |||

|---|---|---|---|---|---|---|

| 2D | 3D | Length | Depth | Height | ||

| A160.6 2D &3D | 6μm | 10μm | >160mm | >160mm | 60mm | 1 |

Pliki do pobrania

Especialistas en el diseño y fabricación de sistemas de medida basados en visión artificial para aplicaciones industriales

Reserve una demostración de producto en línea de cualquiera o todos nuestros sistemas